Inverter Brazing Equipment is explained as follows:

One of the key elements of brazing is fusion of wax.

The quality of brazing products largely depends on the condition of molten wax.

Keeping the temperatures of the "work" (objects to join by brazing) and wax at almost the same level is said to make wax fuse better and eventually create a "stronger" and "more beautiful" finish.

Fusing of wax alone does not make good brazing.

Therefore, the control and regulation of temperature appears to be crucial to quality brazing.

The most important point is the process of determining heating time while confirming the condition of wax fusion.

The benefit of resistance brazing is that once the heating time, etc are determined and under control, wax can be fused always under the same condition. Thus, the resistance brazing is a good processing method to ensure products of uniform quality in mass production.

In the resistance brazing, when wax starts melting, the contract resistance between the work and wax varies letting the electricity pass through easily and thus, the same level of electric current will no longer generate as much heat as before.

Therefore, it becomes important to raise the current value by stages to keep wax in a heat-generating condition so that the temperature of wax can be retained at a certain level till the state of its fusion becomes appropriate.

※ Our company's inverter brazing equipment can provide an 8-stage control in current value.

The points of control in heat generation by conventional alternating current welding equipment (AC welder) are, in general, frequency (resistance welding time) and power (phase control).

Another point is changing of secondary voltage by "trans-tap" (change of output ranges by selecting tap of transformer).

AC welders are widely used because they are inexpensive equipment.

However, as more strict control of wax has been required recently, inverter resistance brazing equipment has increasingly been in demand.

The reasons for such needs are as follows:

Electricity control for resistance brazing equipment

When pressure and power are applied, the wax inserted between works starts melting because of the heat generated as a result of contact resistance between works and wax.

Once wax starts melting, the contact resistance is reduced and electricity passes through easily and thus, the level of heat generation goes down.

Then, it becomes necessary to raise current value by stages in order to keep a certain level of heat generation and melt wax.

Because works and electrodes also generate heat, metal's specific resistance gradually increases. As this inevitably affects heat generating action, it becomes necessary to raise current value.

The welding source that can control these factors enables contacts in a good state of fusion in which wax penetrates into works better.

Why inverter control is better?

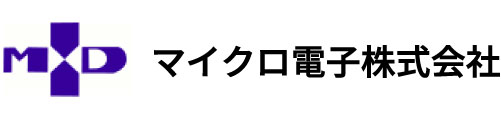

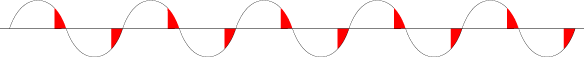

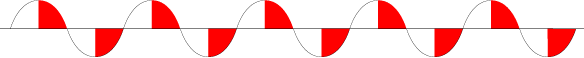

Most of regular AC welding sources control only phase and cycle of sending a current (time) stepwise and have no automatic control of "tap change". Therefore, the controlling must initially be started with short time of current supply with the result of long intervals of the passages of current as shown in the chart below.

For example, if the peak current sending is set at 80% in the 3-stage current supply, it will be necessary to send a current in incremental steps from 20% →50% →80% and determine the corresponding "transtap".

【1st-stage current supply 20%】

【2nd -stage current supply 50%】

【3rd-stage current supply 80%】

As the electric current cycle is about 20msec, there are intervals of 8msec in the 1st-stage.

The 2nd stage and 3rd-stage will have intervals of 5msec and 2msec respectively.

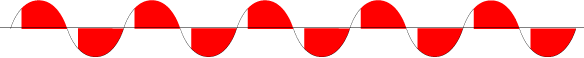

In the case of inverter 3-stage control, the flow of electricity will be as follows with almost no intervals.

【1st-stage current supply】

【2nd-stage current supply】

【3rd-stage current supply】

As the current value and supply time can be flexibly controlled within the specification, the setting of brazing is easy. As there are almost no intervals, it is possible to keep the temperature of wax until it melts smoothly and reaches the most desirable condition of fusion.

As it is clear from the comparison of the wave form charts shown above, inverter-controlled brazing equipment provides efficient heating. Thus, it is easy to determine setting for brazing.

Summary

Inverter brazing equipment introduced by Micro Denshi Co., Ltd. can control electric current supply stepwise up to 8 steps. As the equipment can meet the requirements for an accurate and strict control, users can determine conditions for good brazing more quickly compared with the conventional AC welders.

However, its temperature-controlling function is yet to be developed and currently the brazing technology significantly depends on users' (engineers') experience.

This equipment is likened to a high-powered sports car.

Its high performance can be experienced through the driver's driving ability.

It is definitely easy-to-control equipment. We hope that its performance based on the inverter power source and the 8-stage current supply will be utilized to a full extent for brazing of products of better quality.